DTW-110(8R) - General Field

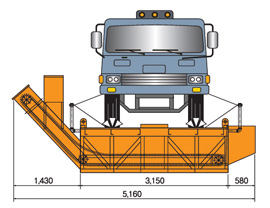

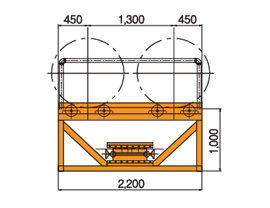

Drawing

※ The above products and specifications can be changed to improve product quality.

Specification

| MODEL | DTW-110 (General Field) | ||

|---|---|---|---|

| Equipment Specifications | 2,200(W) * 5,160(L) * 1,000(H) | ||

| Equipment Weight | 4,700kg | ||

| Appicable Vehicle | 25Ton, Large Vehicle | ||

| Washing Time | 45sec | ||

| Processing Capacity | Max. 640 Vehicles/Day(8 hours/day) | ||

| Electric Power Types | 220V / 380V 3-phase, 60Hz | ||

| Power Consumption | 15.5Kw | ||

| Operation Method | Automatic tire washing system by proximity S/W detection | ||

| Water Pressure | 3~4kg/㎠ | Sludge | Automatic Discharge |

| Areas difficult to supply 3-phase power |

※ New product of energy-saving ROLL type, patented Inquiry on the Portable Automatic Tire Washer (Single phase 220V, combined with a self-generator)

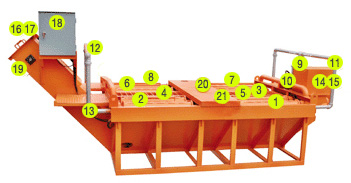

Name of major parts

| 1 | Roller | 8 | Roller | 15 | Roller drive motor (in motor protection cover) |

|---|---|---|---|---|---|

| 2 | Roller | 9 | Submersible pump | 16 | Conveyor Motor Protection Cover |

| 3 | Roller | 10 | filter | 17 | Conveyor drive motor (in motor protection cover) |

| 4 | Roller | 11 | Piping water pipe | 18 | Control Panel |

| 5 | Roller | 12 | Sprinkling piping pipe on discharge side | 19 | Sludge discharge chain |

| 6 | Roller | 13 | Lower water piping line | 20 | Safety footrest |

| 7 | Roller | 14 | Roller guard motor protection cover | 21 | Built-in roller chain |

Three wheel method

-

01

Vehicle entry

The vehicle to be wheeled slowly enters the automatic guide line of the wheel drive machine, and the front wheel of the vehicle is seated between the forward rolls.

The vehicle to be wheeled slowly enters the automatic guide line of the wheel drive machine, and the front wheel of the vehicle is seated between the forward rolls. -

02

Simultaneous three wheel

When the vehicle's gear is in neutral, releasing the brakes, the auto-sensing device operates, carries out the three wheels, and thoroughly cleans the dirt on the inside and outside of the wheels and the bottom of the vehicle.

When the vehicle's gear is in neutral, releasing the brakes, the auto-sensing device operates, carries out the three wheels, and thoroughly cleans the dirt on the inside and outside of the wheels and the bottom of the vehicle. -

03

Rear and lower vehicle rear

The rear wheel is placed slowly between the front rolls as in the case of the front wheel, and the gear is neutralized. When the brakes are released, the dirt of the vehicle is completely cleaned by the operation of the automatic sensor.

The rear wheel is placed slowly between the front rolls as in the case of the front wheel, and the gear is neutralized. When the brakes are released, the dirt of the vehicle is completely cleaned by the operation of the automatic sensor. -

04

Vehicle entry

Once all three wheels have finished, you can gradually move out of the wheel gear.

Once all three wheels have finished, you can gradually move out of the wheel gear. -

05

Automatic discharge of sediment

The wheel-drive unit is fully automatic for the next wheel of the next vehicle, and it replaces the wheel, so it returns to the waiting state in the shortest time.

The wheel-drive unit is fully automatic for the next wheel of the next vehicle, and it replaces the wheel, so it returns to the waiting state in the shortest time.

Advantages of ROLL type system

01. Strength design considering durability

ROLLER is made of high-strength PIPE, circular BAR welded to ROLLER as well as to prevent the slip of the tire during driving, given vibrations to rotate when a tire of ROLLER by the water pressure to be injected in the lower part even misty mud between wheels groove Designed to be fully wheeled.

02. Vehicle sensing device by proximity S/W

S/W is attached between ROLL and ROLL to detect the vehicle, so that the wheel can be turned into three wheels. TIMER can be incorporated to adjust the wheeling time according to the field conditions and soil condition. Also, the breaker is built in for over load of MAIN power.

03. Anti-reverse device

It adopts RATCHET to prevent the reverse rotation of the roll, thus making it easy to proceed when entering or exiting the vehicle. It also protects the reducer by preventing breakage of the roll and chain during rapid start.

04. Automatic discharging of soil sediment by SCRAPER

The powerful CONVEYOR CHAIN and SCRAPER developed by Dongseo will automatically remove sediment from the soil and install a sediment guide chute in the sediment outlet, which is a perfect product to maintain a clean site at all times, unlike other products.